An idea that saved a crop, children, farmers and women in one go

13-September-2013

Vol 4 | Issue 37

In 2007, the district administration of Baran in southeastern Rajasthan was faced with a dilemma. With local farmers on the verge of giving up the cultivation of amla, or Indian gooseberry, they were at a complete loss as to how to prevent this trend.

That’s when a local food and nutrition scientist came up with a plan. She proposed that amla be distributed as part of the mid day meal for children in primary schools.

|

|

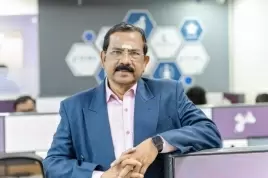

Thanks to the efforts of Dr Sarla Lakhawat, scores of women from the Sahariya tribe have been able to form Self Help Groups (Photos: WFS)

|

As gooseberry, a sour fruit rich in Vitamin C, couldn’t be consumed raw, she recommended it be processed as candy, murabba (compote) and laddus (Indian sweetmeat).

To deliver on this idea, she advocated the involvement of women self help groups (SHGs) for processing and distribution.

Her idea ended up serving multiple purposes – not only did it boost amla production; it ensured critical nutrition for children and gave women a shot at self-reliance.

With innovative thinking and a sound scientific approach, Dr Sarla Lakhawat, who works at the Krishi Vigyan Kendra (KVK) in Anta, a block in Baran district, has managed to fight the region’s triple curse of acute malnutrition among children, tough agricultural challenges and the poor status of women.

In the process, the scientist has given not just a new lease of life to families that were earlier languishing in hopelessness, she has also managed to motivate scores of women, particularly those from the impoverished Sahariya tribe, to fight for their rights by helping them form a vast network of 350 SHGs.

Says Lakhawat, “Amla is a cheap fruit and I knew in this way we would be able to cover a critical nutritional gap in our children. Also, since the involvement of women has many advantages we encouraged them to come forward.

“While the SHGs were trained in amla processing, we found out from the Education Department the number of Mid Day Meal nodal agencies in the district. Around 56 SHGs were formed in different villages and they took on the responsibility of catering to one nodal agency each.”

The SHGs were encouraged to expand their work and they started putting up stalls in melas (fairs) across the district to retail the amla products. The endeavour became a huge success.

Farmers, who were on the verge of giving up the cultivation of amla and were cutting down amla trees planted by the government, got back to work planting them. From 334 acres in 2007-08 the cultivated area of amla increased to 1235 acres in 2011-12, a leap of more than 200 per cent.

Lakhawat has a strong development agenda and the KVK at Anta, where she was posted in June 2005, provided her with the perfect environment to implement her ideas. Located 23 kilometres from the district headquarters, this KVK functions as an innovative science-based grassroots institution.

Besides providing a fillip to amla production, Lakhawat has done key work on finding ways to fight malnutrition particularly prevalent among the Sahariya tribals. Her research on soyabean, a major local crop, presented a practical solution to this challenge.

Though farmers gave their entire harvest to the oil mills, she advocated that women use soyobean flour at home.

“I told them it is a great source of protein containing significant amounts of all the essential amino acids and encouraged them to mix one kilo of soyabean flour with nine kilos of wheat flour.

“Initially, they did not want to consume soyabean flour because it has a bitter taste and sticks to the throat. So I taught them a processing method to make it palatable,” she elaborates.

Besides advising them on giving proper nutrition to their families, Lakhawat has connected with the women of this remote region by assisting them to organise themselves into SHGs.

While one attempt was through the amla products scheme, another revolved around providing skills training in embroidery and stitching to transform them into entrepreneurs. In 2010, Baran Best, an outlet for sale of amla products and readymade garments made by the SHG women, was set up.

This talented agri-scientist, who has recently been conferred with the Swami Sejhanand Saraswati Outstanding Extension Scientist Award 2012, also has a yen for technology.

She developed a post-harvest unit to process garlic using solar energy. The technique has enabled the garlic farmers of Anta to value-add their produce and connect with the international market.

Lakhawat recalls a time when local farmers had been forced to sell garlic in the mandi for as low as Re 1 a kilo.

“They had resisted selling at first in the hope of getting better prices. But the produce started germinating and things came to such a pass that they were ready to offer a full tractor-load, approximately 6-7 quintals, for just Rs 500,” she remembers.

|

|

Dr. Sarla has been able to talk Sahariya tribal women into using soyabean flour in their family diet to combat malnutrition in the region.

|

On searching the Internet for a way out, she realised that there was a lot of demand for garlic granules and powder. She then made a yellow page in her name and invited business inquiries. The garlic for international markets had first to be dried and then ground into powder.

To do this, Lakhawat got a solar dryer installed at a cost of Rs 90,000, under a Department of Science and Technology (DST) project in February 2009. The dryer could process 8-10 quintals at a time.

“We purchased 60 kilos of organic garlic and made granules, making sure that the garlic didn’t lose its colour, texture, aroma or taste. We sent eight samples of 250 grams each for approval to people who had sent us business inquiries. Four got approved. Right then I knew I had found a market for our farmers,” she says with a smile.

Thereafter, Dr Lakhawat began imparting training to farmers by selecting two from each village in the garlic cultivation region.

In January 2011, they were able to export 2,550 kilos of granules to New Zealand and Singapore. Granules that cost Rs 49 per kilo fetched them a hefty Rs 300-900. While the dryer at the KVK catered to 27 villages, three more have been acquired with NABARD funding.

There is a distinctly different air about Anta and its surrounding village today. Mud homes have given way to brick structures, the fields are bountiful, the children go to school and women have become proud entrepreneurs. A lot of this change can be attributed to Lakhawat’s hard work and inspiration. - Women's Feature Service