How Two Friends Built A Rs 6-Crore Eco Startup Offering Green Alternatives to Plastic

Rama Devi Menon

|

06-October-2025

Vol 16 | Issue 41

While the world is battling the ill effects of plastic bottles, especially single-use ones that harm the environment and pollute the soil, two childhood friends have come up with an eco-friendly alternative.

Pradeep Kokkatt (45) and Aliasgar Vora (49), who were looking for a sustainable substitute for non-biodegradable plastic bottles, launched Greenbio Products in November 2019. The company operates under the registered name Eight Specialist Services Pvt Ltd.

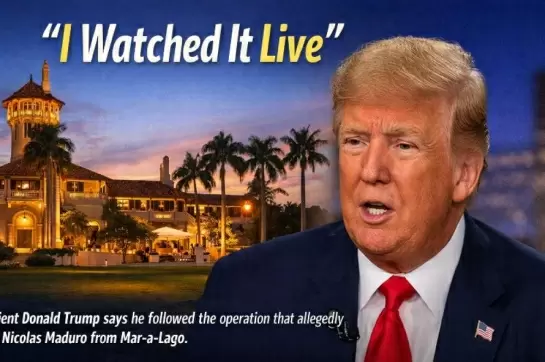

| Childhood friends and founders Pradeep Kokkatt (right) and Aliasgar Vora, the minds behind Greenbio Products, offering biodegradable alternatives to plastic (Photos: Special Arrangement) |

The company’s product range includes biodegradable carry bags, compostable garbage bags, eco-friendly cling films, wrapping sheets, water bottles, D-cut bags, and grocery bags.

“At Greenbio Products, our journey began with a simple yet powerful mission: to combat the escalating crisis of plastic pollution by offering ISO 17088 standard sustainable, biodegradable alternatives. Recognizing the environmental toll of traditional plastics, we set out to develop products that not only serve their purpose but also return to the earth harmlessly after use,” says Pradeep, Founder & Managing Director.

“By embracing a cradle-to-cradle philosophy, we aim to close the biological cycle, ensuring that our products decompose naturally, leaving no trace behind. Sustainability isn't just a buzzword for us; it's a responsibility. We are dedicated to creating eco-friendly solutions that help people and preserve the health of our planet simultaneously,” adds Director Aliasgar.

From bottles and caps to flexible films and raw materials, each product is designed to decompose safely without leaving harmful residues.

“We use raw materials compliant with ASTM D6400, EN 13432, ISO 17088, and approved by the Central Pollution Control Board (CPCB) of India. Every product we offer—whether a carry bag, bottle, food wrap, or garbage liner—is made with the environment in mind, using materials like cornstarch-based bioplastics and other plant-based sustainable alternatives,” notes Pradeep.

Aliasgar explains that conventional plastic packaging takes hundreds of years to break down, often ending up in oceans, landfills, or incinerators. A large portion of these bottles are never recycled and end up adding to the pollution problem.

| Greenbio Products manufactures sustainable bottles, bags, and films that meet global compostability standards |

That’s where Greenbio Products steps in. “Our packaging breaks down within 3–6 months under composting conditions, leaves no toxic residue or microplastics, uses renewable and non-toxic materials,” says Aliasgar.

Their clients include retailers and supermarkets, hotels, cafés and restaurants, event planners and hospitality services, food delivery businesses and cloud kitchens, NGOs and government programmes, and eco-conscious manufacturers and distributors.

“We use cornstarch-based technology for manufacturing, focusing on durability and ensuring the products are compostable and chemical-free. We use certified compostable materials that are safe for people and the planet,” says Pradeep.

“Instead of using traditional materials like paper or glass, we have developed bioplastic granules from polylactide (PLA), which are made from natural resources like corn and sugarcane,” shares Aliasgar

PLA, or polylactide, is a bioplastic made from renewable plant sources such as corn or sugarcane. It resembles conventional plastic in appearance and texture but naturally decomposes under composting conditions.

This PLA is combined with other biodegradable materials to make bottle preforms using injection moulding, while the caps are made using either injection or compression moulding.

The granulated PLA is used to make preforms that can be blown into bottles of any size — from 100 millilitres to 1 litre. Preforms are small, test-tube-shaped moulds made from biodegradable plastic. They serve as the starting form in bottle manufacturing. Once heated and expanded in blow-moulding machines, they take the final bottle shape.

Even the caps and labels are fully biodegradable, unlike normal PET bottle caps that cannot be recycled.

The price of garbage bags is about Rs 500 per pack, typically containing 200–300 bags depending on size. The price of PLA preforms varies based on order volume and customisation. “We provide a tailored quote once we understand the bulk requirement on a monthly basis,” says Pradeep.

Pradeep and Aliasgar hope to take their technology to manufacturers across India and eventually reduce plastic waste globally. “Our mission is to promote sustainable living by offering eco-friendly alternatives to conventional plastic bags, helping individuals and businesses make a positive impact on the environment.”

“We initially manufactured film grade products,” shares Pradeep.

They later started Greenbio with an investment of about Rs 2.5 crore. The company reported a turnover of Rs 6 crore in FY 2024–25. “We manufacture and sell in the domestic market and export raw materials to all major cities and States in India and to the Middle East,” says Pradeep.

Greenbio’s head office is in Kochi, Kerala. Raw materials are produced in Baramati, Maharashtra, preforms in Tamil Nadu, and caps in Kerala. The company has about 10 core employees and 50 contract workers. “Our aim is to have production facilities in different parts of the world as this is the need of the hour,” says Pradeep.

| Greenbio’s biodegradable products are made from cornstarch and plant-based bioplastics that leave no toxic residue |

Hailing from a traditional family, Pradeep holds a Bachelor’s degree in Computer Science from NSS College. He lives in Kochi with his wife, Dr Sini S Nair, an Ayurveda doctor and medical coding instructor who also serves as a director in the company, and their daughter, Tanisi, who is in Class 6.

He has earlier worked as a freelance corporate advisor at Namami Purnagram, Managing Director at Eight Specialist Services Pvt Ltd, and CEO of Eight Consultants. “I am thankful for the excellent support and motivation I received from my family, and above all, the blessings of God,” says Pradeep.

Aliasgar has served as the Vice President of the Association of Compostable Products in India (ACPI) and is the founder of Sunny Enterprises. He is pursuing his Ph.D. from Sage University, Indore, specialising in biodegradable polymers.

He completed his Master of Science (M.Sc.) in Chemical and Industrial Polymer from Sardar Patel University, Gujarat. In 2017, he founded Sunny Enterprises, which manufactures green bioblends — bioplastic resin blends and compounds. He was also a partner in Raj Packaging, a manufacturer of compostable shopping bags, films, and carry bags.- ©TWL